MAB Engineering

Home » MAB Engineering

Warehouse Layout Design and Management

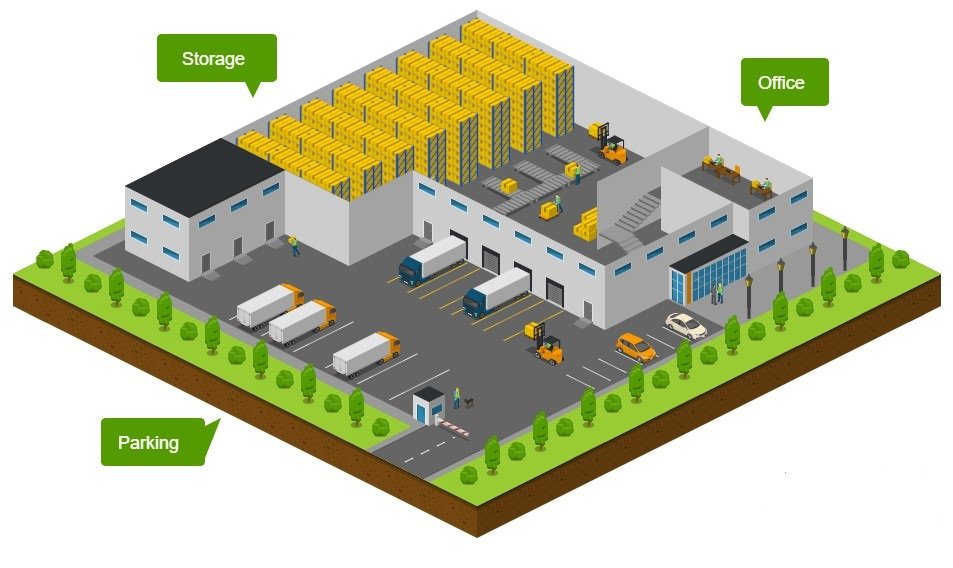

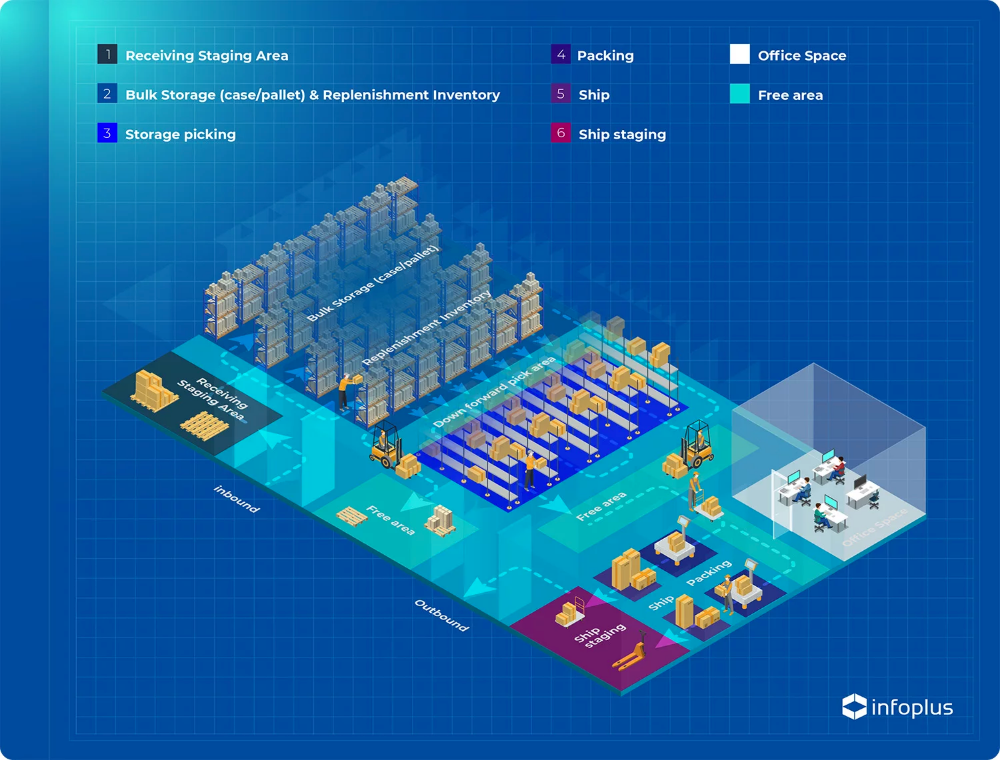

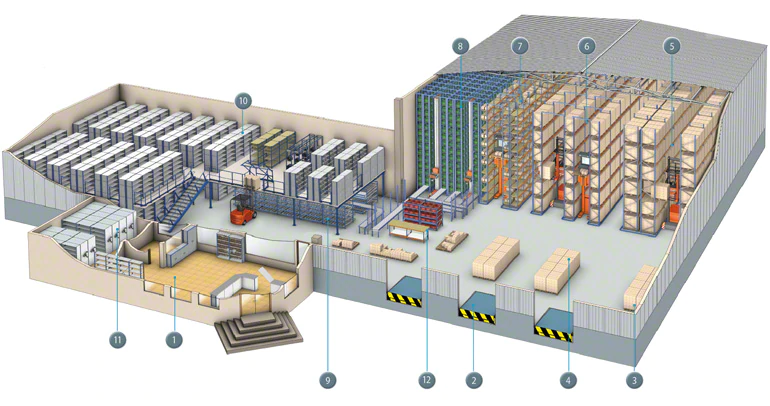

Warehouse Layout and Design service creates warehouse designs that maximize capacity and achieve the desired service levels while reducing operating costs. We create a design that includes not only the detailed physical layout but also an operations manual to ensure the best possible utilization. Each optimized distribution center/warehouse design and layout that we produce is customized to your specific needs. We can help you optimize your current operation or create an efficient new warehouse/distribution center design.

Our Best Service:

• Selecting Warehouse Location.

• Warehouse Design and Layout.

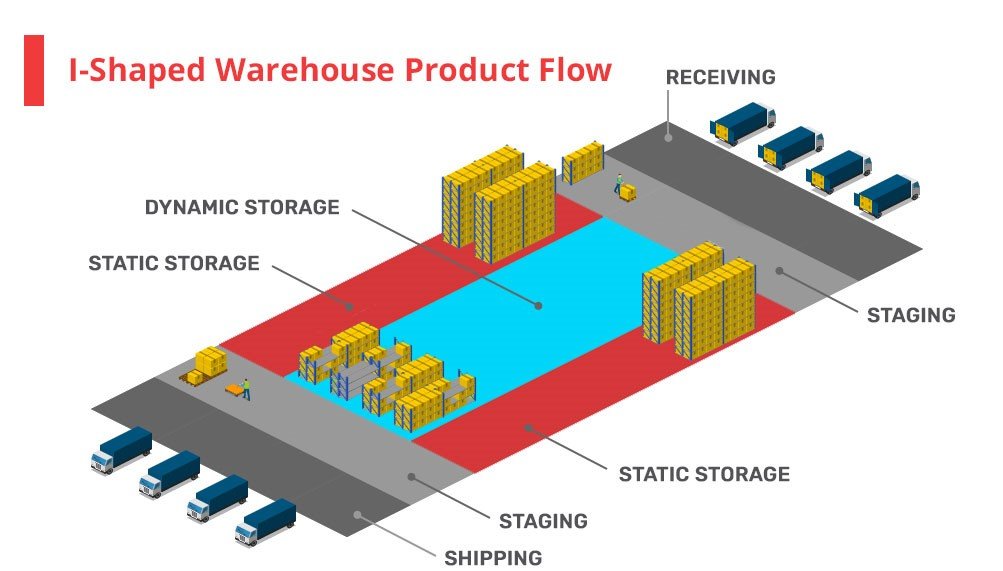

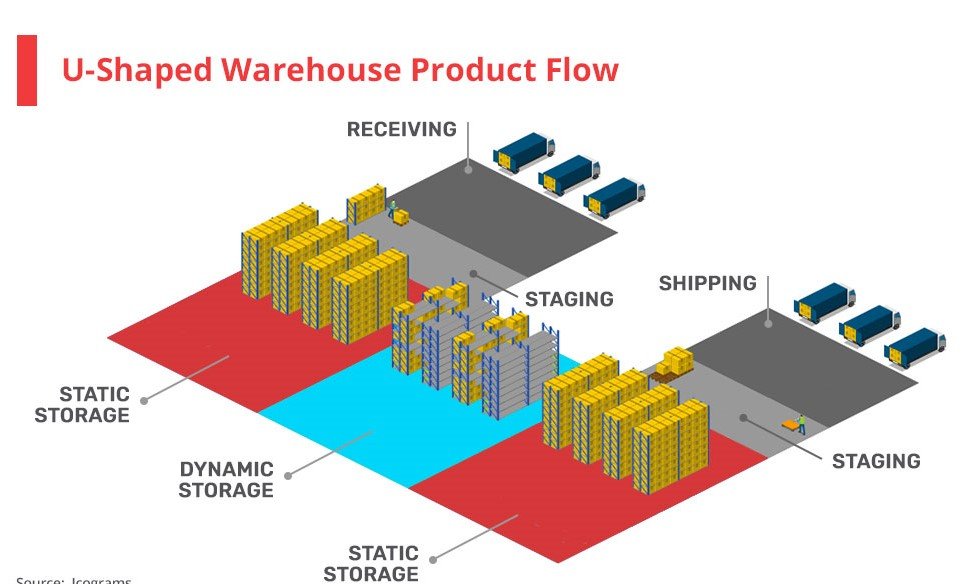

• Redesign Warehouse Operation, Resource Utilization, Storage System and Product Flow.

• Lean Warehousing and Operation Management.

• Efficiency Improvement and Performance Management.

Warehouse Location:

The location of the proposed warehouse facility is likely to be a key driver of implementation and on-going transport costs. The MAB Engineering can assist in this decision using elements of the Network Design and Supply Chain Mapping tools. The preferred locations can be checked for cost and availability of sites and/or existing buildings.

Mab Engineering selecting the location for design warehouse position based on important factors which include

• Land cost, labor availability, travel minimization and total cost.

• Access to transport networks & Transport links for staff.

• Goods traffic flows & Proximity to ports and airports.

• Location of suppliers and manufacturing points.

• SWOT Analysis.

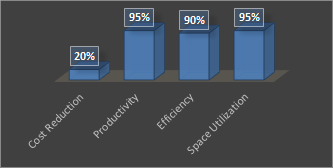

Why does a company need a well-designed Warehouse & WMS?

For Real-time stock visibility and traceability.

- To improve productivity and Efficiency.

- To improve quality and safety.

- To reduce lead time from suppliers.

- To Accurate stock and Reduction in miss-picks.

- For Automatic replenishments & Reductions in returns.

- For Accurate reporting and Remote data visibility

- For Improved responsiveness and improved customer service.

- Minimized paperwork.

- And Reduce Inventory Holding Cost.

Special Feature of Warehouse Design and Layout by MAB Engineering:

By considering Four fundamental factors FAST (Flow, Accessibility, Space and Throughput) we are designing layout and warehouse operation based on –

- Ergonomic Design and Workstation

- ABC Analysis

- Lean Operation

- Just In Time (JIT)

- Fast Input First Output (FIFO)

- Last Input Fast Output (LIFO)

Warehouse Layout and Design: The detailed layout and design of the preferred facility option will include, performance specifications, equipment layout, facility footprint and building design and cost, (new building), specification of static and mobile materials handling equipment, high level process design, detailed implementation and warehouse operational costs.

6Rs Logistic: MAB Engineering Special emphasis on

Material Flow based on “6Rs” Logistics. The “6Rs” of

logistics describe the logistic targets as the delivery of

- the right goods at the

- right time in the

- right quantity and the

- right quality at the

- right location at the Office

- Right costs.

Lean Warehousing and Operation:

This is where lean techniques are using within a warehouse environment. The idea is to identify the activities within the warehouse that absorb resources but don’t create additional value. Lean talks about the seven wastes or muda that lean management seeks to eliminate.

Lean management deeply works in warehouse to remove deadly seven wastages.

- Transportation (driving an empty forklift)

- Defects (time spent correcting errors such as miss picks)

- Inventories (congestion at the inbound and outbound areas)

- Motion (interrupting movement such as staging product before put-away)

- Waiting time (bottlenecks at pick locations)

- Overproduction (holding too much inventory) and

- Over processing (performing unnecessary steps such as labelling and checking).

Five Reasons for Choosing MAB Engineering

Stability

MAB Engineering is committed to long-term solutions. You can trust that our team of experts will be there for you today, tomorrow and in years to come.

Efficiency: MAB Engineering solutions are scalable and able to grow with your business. You can always upgrade or retrofit.

Quality: As a systems specialist and original equipment supplier, MAB Engineering provides high-quality solutions from a single source, specifically designed to meet your challenges.

Reliability: Thanks to our Customer Service & Support network, MAB Engineering ensures smooth operation of your system, both during and after installation.

Know-how: MAB Engineering solutions are always up-to-date with the latest technological standards and can be easily integrated into an existing (IT) landscape.

Racking System Installation

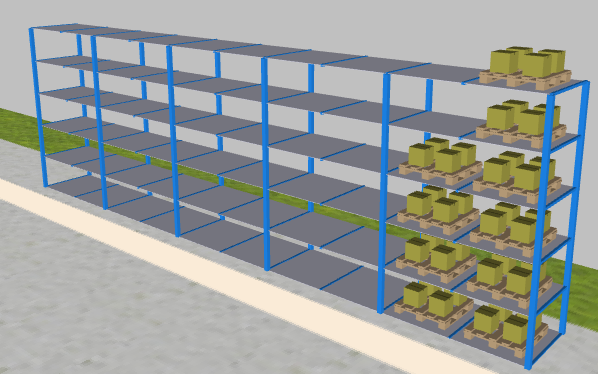

Selective Shelving Rack:

The most economical and easiest to install racking system is Selective Shelving Racking in the warehouse racking system. Where design consists of light or heavy duty posts, low profile single rivet or double rivet beams with boltless shelving means riveter. No Bracing required in shelving racking system.

Various types’ boxes, cartons and bulk goods are perfect for storing in selective shelving racks. Manual and automation can be applicable in this system.

- Advantage:

- Ergonomically suits for uses.

- Elasticity to be configured to any size best suited to the available height and layout.

- Modularity through range of components enables easy expansion in future which fits seamlessly to the existing system.

- Adaptability to varying load sizes beam with adjustment.

- Wide Range of beam and upright sections enables to choose the most

Application Area:

- Garments & Textile Industries

- Food & Beverage Industries

- Pharmaceutical Industries

- Electrical & Electronic Industries

- Distribution & Super Shop

- Steel Manufacturing Industries.

- Chemical & Leather Industries

- Plastic and Furniture Industries.

- Service Industries

Pallet Rack:

Pallet racking systems are material handling solutions designed to store inventory, products, and materials. These solutions are excellent at utilizing vertical space within the facility.

We offer pallet racking solutions styles that include teardrop pallet racks, slotted pallet racks, structural pallet racks, column reinforcement, drive-in storage, push back storage, gravity flow storage, narrow aisle storage, horizontal pallet transfer systems, and more!

Our racking systems provide innovative solutions to improve pallet rack safety, including column sentry reinforcements, slant back/offset uprights, beam-to-column locking mechanisms and seismic base isolation technology. From 100% selective pallet rack, to high density storage rack systems, to specialized options, we can provide a customized racking solution to meet any storage need you have.

Advantage:

- Available in numerous capacities, sizes, and configurations for custom fit.

- Immediate access to all storage

- Can be made from roll formed, structural steel, or a combination of both materials.

- Easy to adjust shelf heights

- Inexpensive – lowest cost option per square foot.

- Easy product accessibility – each lane is one SKU. High-density storage and more flexibility with multiple SKUs

- Can be custom-designed.

- Low maintenance pallet storage system

Mezzanine Rack:

A mezzanine is a “middle” floor that is usually between two levels of a building or unit. Installing mezzanine rack will help to provide the owner with almost double the amount of storage space. Mezzanines, which are free-standing structures, are great for industrial spaces because it allows organizations to use their area in an efficient manner. Modular in design, they can be expanded both upwards and outwards indefinitely, allowing the use of the full height of a building.

These systems are definitely a great way to utilize every inch of your company’s workspace and will provide an increased amount of efficiency and organization to your enterprise

Common Uses Area: Warehousing, Distribution, Retail, Office, Storage, Production and Manufacturing.

Advantages:

- Effective-Cost effective alternative to expensive building expansions or relocations.

- Optimization-Make maximum use of space and increase the integration of Additional Levels.

- Flexibility-Easy to Install, A self-supporting construction or as platform supported racking.

- Modular and Customizable

- Operations are more Efficient and Reliable